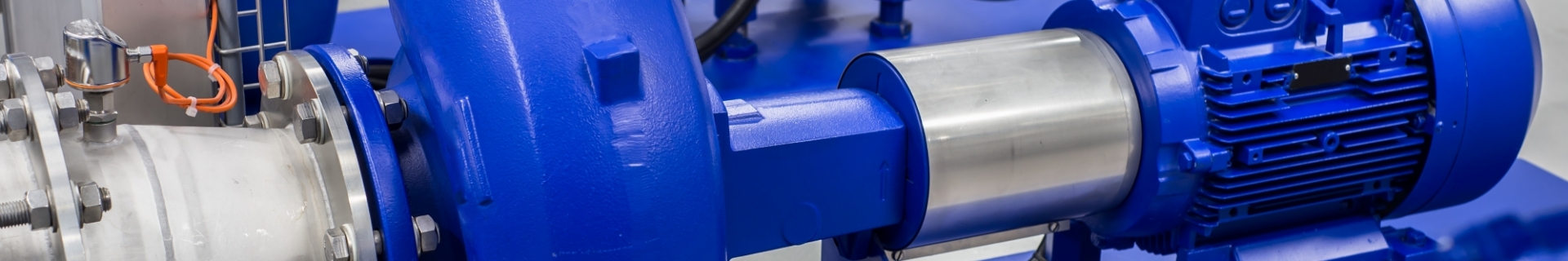

Since 1955, Northwest Electric has prided itself on being the Midwest leader in quality electrical repair and customer service for all industries. In order to do this Northwest Electric offers repair services for an extensive range of horsepowers and categories of electric equipment along with following strict quality control procedures and tests. Northwest Electric continually strives to advance its range of electric repair services and quality control processes to ensure long term customer satisfaction and success. Call 800-456-4264 to learn more.

With services on horsepowers ranging from, Fractional to 5,000 HP / 4160 volts (AC) and Fractional to 2,000 HP / 500 volts (DC) Northwest has greatly expanded its offering over the years while still maintaining its high level of expertise. This expertise is not limited to just standard AC and DC but covers Drum/Roller, Explosion Proof, Slip Ring, Traction, and Wound Rotor motors. Along with all of this Northwest also offers onsite and in house generator repair including StandBy, PTO Drive, and Portable generators. Specialty repairs such as lifting magnets, control coils, magnetic rollers, and brake coils. All of this means that Northwest can provide you with a repair solution for any of your facility's requirements.

In order to ensure that Northwest is providing the highest quality repair possible, we strictly follow the EASA AR 100, IEEE, NEMA, and ANSI standards for all electric motor repairs. In most cases, Northwest will go above and beyond these standards to ensure you receive the highest quality repair. Coreless, Surge/HiPot/PI, Full Voltage, Vibration Analysis, TIR, Balancing, Low OHMS Resistance, Rotor Bar, Bar to Bar, and Dynamometer testing are standard on all corresponding motor repairs. These quality tests are just another way in which Northwest Electric takes the extra step to ensure the highest quality repair and to make sure you receive the level of customer service you deserve.

So don't risk the quality of your repair or customer service to anyone else.

When a motor is not functioning at the highest capacity, it affects the output of the operation including loss of time, resources and/or production. Northwest Electric is a proud provider of motor repair, putting the customer at the center of our service model to ensure a quick turnaround time. We strive to accurately repair equipment and put it back into service as soon as possible.

Our team will check all components of the motor to ensure that a proper diagnosis is made. We'll then work to resolve the issue quickly and effectively, according to standards that are even higher than the industry average. Learn more about Northwest Electrics' Quality Control Procedures.

Range of Horsepower:

- Fractional - 5,000 HP (AC) 4160 volts

- Fractional - 2,000 HP (DC) 500 volts

Types of Motor Repair:

AC | DC | Drum/Roller | Explosion Proof | Slip Ring | Traction | Wound Rotor

The following procedures can be performed onsite or in-house:

- Diagnostic Testing and Repair: Our team will perform a series of tests to assess the condition of your generator and provide a diagnosis for the proper repair to bring it back to optimum condition.

- Preventive maintenance: It's much more efficient to detect an issue before it becomes a large problem that may impact your production and/or other aspects of your business. The Northwest Electromechanical Services team can come out to your location at regular intervals (for example, every 6 to 12 months) to replace the oil, check for loose connections, examines and test, and ensure that it is running properly. You need to be able to count on the reliability of your generator. Preventative maintenance ensures your generator is ready to go when you need it.

In addition, we offer:

- Onsite commissioning: Our team can help with the installation of a new generator. We'll make sure it is hooked up properly, running through all of the necessary tests and assessments to have it running correctly per the manufacturer's specifications. This provides peace of mind knowing that your new product is going to function the way it was intended and at the highest level possible.

The types of generators we can service (onsite or in-house):

- Stand-by

- Irrigation

- PTO Drive

- Portable

We offer the following specialty repairs:

- Rectangular Lifting Magnets

- Control Coils

- Magnetic Rollers

- Brake Coils

- Magnetic

Learn More

Northwest Electric has been providing invaluable repair services and quality products to our industry partners in manufacturing, production, mining, processing, utilities, and municipalities for over 65 years. Our commitment to providing our clients with expert consultation and dependable, timely services is our top priority.

Our expansive industry knowledge allows Northwest Electric to be your partner in problem-solving. Call us 24-7 or complete the form below to discover our complete breadth of services.