Northwest Electric capitalizes on a tenured team of experienced and responsive professionals who understand your equipment and production challenges—offering recommendations to positively impact your bottom line.

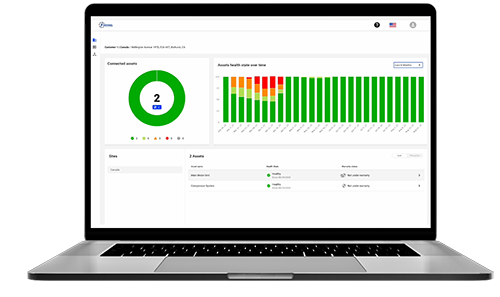

Consistently monitoring your asset behaviors through our Sentinel Program allows you to proactively assess the health of your equipment and predict maintenance concerns before they occur. Our holistic maintenance approach for rotating equipment maximizes efficiencies and minimizes downtime and repair costs.

Our asset management program provides equipment inspections and audits, pricing, storage, maintenance, inventory management, and monitoring. When you partner with Northwest Electric, we assist in meeting your goals to reduce your annual maintenance costs.

The most effective way to save on overall costs.

- Minimize Unplanned Interruptions

- Cut Manual Monitoring Expenses

- Lower Maintenance and Repair Outlays

- Enhance Planned Downtime Efficiency

- Optimize Production Volume

The balance between action and inaction is different for every asset and every plant. Frequent inspections can detect indicators of failure early on but require time and availability to carry out. Northwest Electric vibration experts provide data-informed motor service prioritization based on actual asset health.

PREDICTIVE MAINTENANCE PROGRAM

PREDICTIVE MAINTENANCE PROGRAM

Program Features

- Asset Health Monitoring: Active motor scan devices mounted on critical assets measure vibration (3-axis), temperature, and run hours to identify and flag potential issues before they occur.

- Asset Inspection & Detailed Reporting: Insightful inspection and vibration analysis testing provide detailed reports for strategic decision-making and planning. Dashboard to compile all data delivered from Gateway.

- Northwest Electric Service & Expertise: Our experienced team designs a service portfolio tailored to your needs to include RCBM1 and PdM2 repair capabilities.

Key Benefits

- Early recognition of anomalies: Demonstrating how sensor data provides more timely information than scheduled–vibration analysis.

- Summary reports on overall asset health: Not all equipment will have issues during the tested time period. Having the best data on asset health is valuable.

- Accurate recommendations and root cause identification: Proof-points of how the combination of monitoring and Northwest Electric expertise delivers actionable results.

MANAGED INVENTORY PROGRAM

MANAGED INVENTORY PROGRAM

Program Features

Identify:

Northwest Electric provides a complete on-site audit of your critical motors to help you document your assets. The audit helps identify functional equivalents, which can help you to consolidate your inventory, ultimately saving you money.

Analyze:

Working with the Northwest team helps you create a backup plan for all critical assets. Determining which spares need to be stocked at your location, a Northwest warehouse, or delivered timely from one of our strategic vendor's facilities improves uptime.

Manage:

Northwest Electric helps manage your spares to give you the confidence that assets will be ready for production when needed. The Northwest team ensures your spares are stocked in a clean environment with regular maintenance, meeting all manufacturer's specifications.

Key Benefits

- Service All Inventories: NWE and customer locations to ensure motors are ready once pulled from storage.

- Regular Shaft Rotation and Electrical Testing per Manufacturer's Specifications: Motors are tested before delivery to ensure they're ready for installation.

- Backed by Northwest Electric's Repair Warranty: All motors that NWE repairs come with a 1-year craftsmanship warranty and a 3-year warranty on any NWE rewind.

FIELD SERVICE OFFERINGS

FIELD SERVICE OFFERINGS

Program Features

- Alignment: Ensures that mechanical components are precisely positioned to prevent undue strain, minimizing wear and improving efficiency.

- Balancing: Involves adjusting uneven weight distribution in rotating equipment to prevent vibrations, enhance performance, and extend the equipment's lifespan.

- Vibration Analysis: Assesses equipment vibrations to identify irregularities, enabling early detection of potential faults and preventing failures.

- Onsite

- Remote Monitoring

- Installation/Removal: The proper setup and removal of equipment, ensuring safe and efficient operation throughout its lifecycle.

- Thermal Imaging: Detects temperature variations in equipment, helping to identify overheating or cooling issues that could lead to malfunctions or breakdowns.

- Ultrasonic Leak Detection: Uses sound waves to pinpoint and assess gas or liquid leaks in equipment, preventing energy waste and environmental hazards.

Key Benefits

- Maximizing the life expectancy of equipment: Ensures prolonged operational efficiency and reduces the frequency of replacements or repairs.

- Optimizing planned downtimes: Minimizes production disruptions and maintenance costs by strategically scheduling maintenance activities during periods of lower demand.

- Improving asset reliability: Enhances overall operational stability and reduces unexpected breakdowns, leading to increased productivity and reduced maintenance expenses.

Learn More

Northwest Electric has been providing invaluable repair services and quality products to our industry partners in manufacturing, production, mining, processing, utilities, and municipalities for over 65 years. Our commitment to providing our clients with expert consultation and dependable, timely services is our top priority.

Our expansive industry knowledge allows Northwest Electric to be your partner in problem-solving. Call us 24-7 or complete the form below to discover our complete breadth of services.